An integration with a commercial bioreactor saves space and reduces overall cost

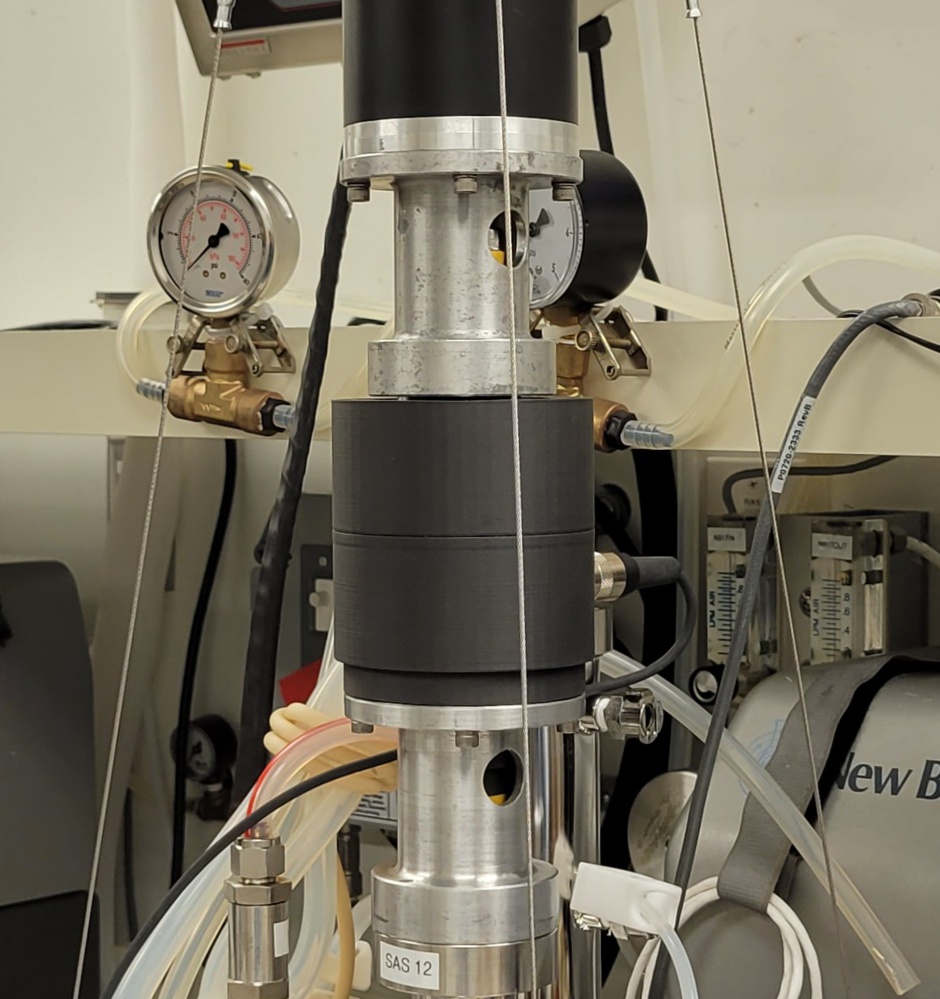

A client with number of Eppendorf Bioflo 310™ bioreactors had a need for more than the three pulse-width modulated (PWM) peristaltic pumps that come stock on the front of the unit. The 310 unit provides for the display and control of three additional external, variable speed pumps through analog current connections on the back of the unit.

But lab bench space was too scarce to add additional variable speed pumps for all of the client’s fermentors. Additionally, the client wanted the pumps to be PWM with the ability to divide-down the feed rate if required.

BME Systems designed and manufactured a retrofit of the stock pump panel that included six pumps instead of three. BME traced the circuitry and rerouted the external pump signals internally to a microprocessor in the retrofit. The microprocessor converts the analog signals to PWM signals that drive each of the same model of fixed speed pumps on the unit. The Bioflo™ software configures the pumps just as if they were external units and can be calibrated in the same way. The casework was designed to match the material, color and fit of the unit exactly.

Variable speed pumps are relatively more expensive than fixed speed pumps. The entire project was implemented for nearly half the cost of implementing external variable speed pumps with a huge reduction in required lab space. The BME Systems Six Pump Retrofit is available for your laboratory!